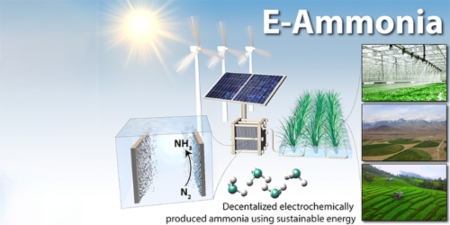

Researchers wish to revolutionize the production of ammonia for fertilizer, so that it can take place at the site of a single farm or greenhouse. The production will be carried out sustainably using electric power, e.g. wind and solar, as well as water and air.

Ammonia is a critical component in fertilizer to ensure production of food globally. Today, ammonia is produced centrally using fossil fuels on large facilities and thereafter it is distributed to end users. The current production method requires both high temperatures of several hundred degrees, as well as high pressures of at least 150 bar. The result is that the production of ammonia, of which 90% is used for fertilizer, accounts for more than 1% of global energy use.

It is therefore of great interest to find alternative methods to produce ammonia. A team of researchers at DTU Physics with Professor Ib Chorkendorff at the helm have already made the first important steps towards this.

“We have produced ammonia in the laboratory using sustainable production methods and at normal temperature and pressure conditions. In the process, we use electricity in the form of electrocatalysis as well as water and nitrogen from the air,” says Ib Chorkendorff.

The new method will in the coming three years be developed in the E-Ammonia project, in which Innovation Fund Denmark has invested DKK 19.5 million.

Ambitious goals

The project’s very ambitious goal is to scale the new production method with a factor of a 1,000, allowing for the process to work for a 1 cm2 area in the laboratory up to a 1 m2 area in the real world. This will be achieved in the same way as with fuel cells, by stacking the cells. If it succeeds, it will be possible to develop facilities that can produce several kilograms of ammonia an hour and are therefore feasible for commercial operation.

"Today, transport costs constitute a significant part of the price of fertilizer, so another suitable market for future smaller ammonia production facilities are agricultural areas in developing countries, where lack of infrastructure results in significantly higher prices significantly"

Ib Chorkendorff

“We imagine that initially that greenhouses and agricultural sites with their own irrigation systems would be interested in being able to produce ammonia themselves. It would be cheaper for them, and it would facilitate dosing ammonia to the plants only when they need it, thereby minimizing loss of unused ammonia from drainage.” says Ib Chorkendorff.

“Today, transport costs constitute a significant part of the price of fertilizer, so another suitable market for future smaller ammonia production facilities are agricultural areas in developing countries, where lack of infrastructure results in significantly higher prices significantly. In these areas, an independent supply of electricity to the production facility with e.g. solar cells would be an obvious choice.” says Ib Chorkendorff.

Large growth possibilities

To ensure that the development of ammonia production is carried in the most optimal way, the company Spectro Inlets will be involved in the E-Ammonia project. The company produces a microchip that is used in an analysis instrument for research in aqueous electrochemical measurements, as well as industrial monitoring, e.g. on biogas production facilities. This system will be developed to measure the production of ammonia.

“This project is a fantastic opportunity to develop our existing microchip to also measure in liquids used for electrocatalytic production of ammonia. We have already made some progress and have initial prototypes ready,” says director Anil Thilsted, Spectro Inlets.

Anil Thilsted adds that the new microchip will also be able to provide opportunities to address other interesting markets, for example the increasing production of batteries for electronic equipment.

The growth opportunities for a new method of producing ammonia are also significant. When the E-Ammonia project ends in 3 years, the goal is to establish a new company for production and sales of new ammonia production facilities.

The American fund, Breakthrough Energy Ventures, is therefore involved as a partner in the project and is responsible for developing the final business case. The fund is founded by Bill Gates and 20 other global industry leaders in an effort to support start-ups that can contribute to a reduction of at least 500 billion tons of CO2 a year. A sustainable ammonia production method is therefore of great interest to the fund.

Ib Chorkendorff predicts that the new production method in the far future will be used for energy storage applications and for fuels for e.g. ships.

DTU Physics

DTU Physics work with, among others, ’Villum Center for the Science of Sustainable Fuels and Chemicals’ to develop solutions for sustainable energy. The research covers fundamental challenges as well as a focus on transforming this to applicable technology.

DTU Physics leads the E-Ammonia project.

Spectro Inlets ApS

Spectro Inlets is a start-up that bases its business on its innovative microchip membrane technology which was developed at DTU Physics.

Breakthrough Energy Ventures

An American venture capital investment fund founded by Bill Gates and 20 other global industry leaders. The fund supports start-up companies that can contribute to reducing CO2 emission by at least 500 million tons annually.

Stanford University

Stanford University has a close collaboration with DTU Physics. In this project, the researchers at Stanford contribute with development of prototypes to the technology for electrocatalytic production of ammonia.