The Danish stone wool insulation manufacturer, the ROCKWOOL Group, is always looking for new ways of understanding the 3D structure of its products. In fact, microstructure plays a determinant role for stone wool’s insulation and mechanical properties, hereby affecting how it responds to different conditions of use and external factors. A cooperation with the Imaging Industry Portal at DTU revealed the advantage of X-ray CT to study the fiber structure of insulation materials and paved the way for better design methods based on 3D-imaging.

Challenge

ROCKWOOL’s insulation materials are made of a complex web of stone fibers, whose size, length and orientation are decisive for the materials’ insulation value and mechanical properties. For this reason it is important for the ROCKWOOL Group to understand how the fiber structure recovers from the compression it is submitted to when packed into rolls and moved.

Collaboration

The analysis of fiber structures on standard X-ray equipement does not always give satisfying results. But the collaboration with the Imaging Industry Portal delivered very good results thanks to a unique set of data acquired on a synchrotron in Switzerland (PSI) and an advanced algorithm especially developed for the project.

Results

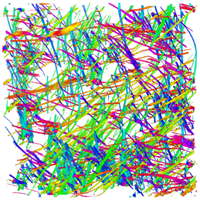

The 3D-pictures obtained through the collaboration allowed the ROCKWOOL group for the first time to categorize fibers according to size and orientation in a very precise way.

|

|

|

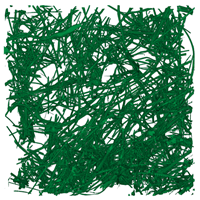

3D-rendering of the fiber structure of stone wool

|

Fibers categorized according to orientation

|

Perspectives

The use of X-ray CT opened up for new and in-depth knowledge, which the ROCKWOOL Group could not have acquired with other methods. The collaboration with the Imaging Industry Portal is continuing and may lead to new material design methods based on the results.