The Danish fish feed manufacturer BioMar entered a collaboration with the Imaging Industry Portal at DTU in order to gain insight into the porous structure of their fish feed pellets. A series of X-ray scans and data analysis at DTU’s local facilities in Lyngby revealed local areas where the pellets’ pore structure ensure optimal oil retention.

A new knowledge, which will, in the longer term, allow the company to optimize its production processes and hereby reduce costs.

Challenge

Transportation is one of the tricky steps of the value chain for fish feed pellet manufacturers. In fact, oil - and the subsequently added nutrients - has a tendency to seep out of the pellets during transportation, causing manufacturers a loss of costly resources. Besides, the growing demand for high-fat products puts even more pressure on the pellets’ cabability to retain the oil phase.

Collaboration

BioMar suspected that the porous structure of their pellets might play a key role in oil retention. The company engaged in a collaboration with the Imaging Industry Portal at DTU in order to gain insights into the porous structure of their fish feed pellets. A master student was appointed to carry out measurements and data analysis for the company, under the supervision of researchers from the University of Copenhagen and DTU.

Results

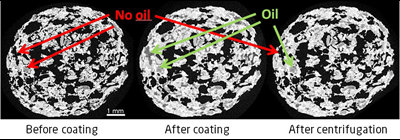

The pellets were measured with and without oil, before and after coating and centrifugation, revealing the optimal pore structure and size to retain oil in the pellets.

Perspectives

The new insights provided by 3D imaging will allow BioMar to explore new ways of optimizing pellet production to ensure maximum oil retention, e.g. by testing alternative raw materials and their impact on the pellets’ pore structure.